Abstract

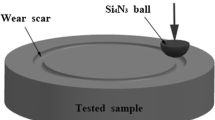

As the main steel used in the aero-engine main shaft bearings, the tribological properties of M50 can directly affect the performance of aero-engine. The purpose of this study is to design the reasonable composition of Sn-Ag-Cu alloy and investigate the wear mechanisms of M50-10 wt.%(Sn-Ag-Cu) composites (MSACC) prepared by SPS sliding against Si3N4 ball from 25 to 550 °C at 12 N-0.25 m/s. XRD, EPMA, FESEM and EDS mappings are conducted to understand the major mechanisms leading to the improvement in the sliding behavior of MSACC. The results indicate that MSACC with different specifications of Sn-Ag-Cu alloy shows excellent friction and wear properties from 25 to 550 °C compared to M50. M50-10 wt.%(50Sn40Ag10Cu) (MSACC-2) shows the distinguished tribological performance for the lower friction coefficients of 0.22-0.61 and less wear rates of 1.7-4.1 × 10−6 mm3 N−1 m−1, which is attributed to the formed excellent lubricating structure consisting of the lubricating film with massive Sn-Ag-Cu alloy and intermetallic compounds formed during the friction process, as well as the underneath mixed layer who can well support the lubricating film due to the good intersolubility between the designed Sn-Ag-Cu alloy and M50 (Fe).

Similar content being viewed by others

References

P. Mukhopadhyay, P.S. Kannak, M. Srinivas, and M. Roy, Microstructural Developments During Abrasion of M50 Bearing Steel, Wear, 2014, 315, p 31–37

L.Q. Wang, B. Peng, L. Gu, and J. Wang, Tribological Performance of M50 Steel Tribo-Parts, ASLE Trans., 2012, 55(2), p 191–198

N.K. Arakere and G. Subhash, Work Hardening Response of M50-NiL Case Hardened Bearing Steel During Shakedown in Rolling Contact Fatigue, Mater. Sci. Tech-Lond., 2012, 28(1), p 34–38

W.Z. Zhai, X.L. Shi, J. Yao, A.M.M. Ibrahim, Z.S. Xu, Q.S. Zhu, Y.C. Chen, L. Chen, and Q.X. Zhang, Investigation of Mechanical and Tribological Behaviors of Multilayer Graphene Reinforced Ni3Al Matrix Composites, Compos. B, 2015, 70, p 149–155

W.Z. Zhai, X.L. Shi, K. Yang, Y.C. Huang, L.P. Zhou, and W. Lu, Mechanical and Tribological Behaviors of the Tribo-Layer with Nanocrystalline Structure During Sliding Contact: Experiments and Model Assessment, Compos. B, 2017, 108, p 354–363

F.A. Essa, Q.X. Zhang, and X.J. Huang, Investigation of the Effects of Mixtures of WS2 and ZnO Solid Lubricants on the Sliding Friction and Wear of M50 Steel Against Silicon Nitride at Elevated Temperatures, Wear, 2017, 374–375, p 128–141

X.L. Shi, Z.S. Xu, M. Wang, W.Z. Zhai, J. Yao, S.Y. Yao, A.Q. Din, and Q.X. Zhang, Tribological Behavior of TiAl Matrix Self-Lubricating Composites Containing Silver from 25 to 800 °C, Wear, 2013, 303(1–2), p 486–494

K. Yang, X.L. Shi, Y.C. Huang, W.Z. Zhai, Y.F. Wang, A. Zhang, and Q.X. Zhang, The Research on the Sliding Friction and Wear Behaviors of TiAl-10 wt.%Ag at Elevated Temperatures, Mater. Chem. Phys., 2017, 186, p 317–326

Q. Shen, X.L. Shi, K. Yang, J.L. Zou, W.Z. Zhai, and Q.X. Zhang, Tribological Performance of TiAl Matrix Composites Containing Silver and V2O5 Nanowires at Elevated Temperatures, RSC Adv., 2016, 6(61), p 56294–56302

Y. Gu, X. Zhao, Y. Li, Y. Liu, Y. Liu, and Z.Y. Li, Effect of Nano-Fe2O3, Additions on Wettability and Interfacial Intermetallic Growth of Low-Ag Content Sn-Ag-Cu Solders on Cu Substrates, J. Alloys Compd., 2015, 627, p 39–47

X.Y. Liu, X.L. Shi, C.H. Wu, K. Yang, Y.C. Huang, X.B. Deng, Z. Yan, and B. Xue, Tribological Behavior of M50-MoS2 Self-Lubricating Composites from 150 to 450 °C, Mater. Chem. Phys., 2017, 198, p 145–153

X.Y. Liu, X.L. Shi, Y.C. Huang, X.B. Deng, G.C. Lu, Z. Yan, H.Y. Zhou, and B. Xue, The Sliding Wear and Friction Behavior of M50-Graphene Self-Lubricating Composites Prepared by Laser Additive Manufacturing at Elevated Temperature, J. Mater. Eng. Perform., 2018, 27, p 985–996

X.B. Deng, X.L. Shi, X.Y. Liu, Y.C. Huang, Z. Yan, K. Yang, and Y.F. Wang, Effect of Ti3SiC2 on Tribological Properties of M50 Matrix Self-Lubricating Composites from 25 to 450 °C, J. Mater. Eng. Perform., 2017, 26, p 4595–4604

R.N. Goldbeck, Iron-Binary Phase Diagrams, 1982, vol 149(1), p 375–384

Y.S. Jin and C.H. Zhou, The Effectiveness of High Temperature Lubrication by In Situ Formation of Graphite/MoS2 Films, Wear, 1997, 205(1–2), p 77–87

Acknowledgments

This work is supported by the National Natural Science Foundation of China (51275370); authors are grateful to Y.M. Li, X.L. Nie, M.J. Yang, S.L. Zhao and W.T. Zhu in Material Research and Test Center of WUT for their kind help with EPMA and FESEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, X., Shi, X., Huang, Y. et al. The Sliding Wear and Frictional Behavior of M50-10 wt.%(Sn-Ag-Cu) Self-Lubricating Materials at Elevated Temperatures. J. of Materi Eng and Perform 27, 4291–4299 (2018). https://doi.org/10.1007/s11665-018-3484-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3484-6