Summary

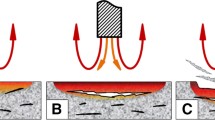

Thermal spallation is a method whereby the surface of a rock is rapidly heated causing small (100–1000 μm) flakes or spalls, to form. When applied to drilling, a supersonic, high temperature (2600 K) gas jet is directed at the rock to provide the heat source and sweep away the spalls.

Previous studies of thermal spallation drilling indicate that penetration rates of up to 30 m/hr (100 ft/hr), approximately ten times greater than commonly obtained using conventional rotary mechanical methods, can be achieved in competent, non-fractured hard rock such as granite. A total direct operating cost for drilling in granite using a flame-jet spallation drill was estimated by Browning (1981) to be approximately $9/m in 1991$ (about $3/ft) compared to “trouble-free” well drilling costs for conventional rotary methods in similar rock to depths of 3 to 7 km (10000 to 21000 ft) of $300 to $900/m ($100 to $300/ft) (Tester and Herzog, 1990, 1992). The Browning estimates for spallation drilling are obviously optimistic in that they don't include capital costs for the rig and associated hardware. However, the substantially higher penetration rates, significantly reduced wear of downhole components, and the high efficiency of rock communition in comparison to rotary methods suggest that substantial cost reductions could be possible in deep drilling applications. For example, in the construction of hot dry rock geothermal power plants where rotary mechanical methods are used for well drilling to depths of (4 to 5 km), about half of the initial capital cost would be required for well drilling alone (Tester and Herzog, 1992).

The current study has focused on gaining a better understanding of both the rock failure mechanism that occurs during thermal spallation and the heat transfer from the gas jet to the rock surface. Rock mechanics modeling leads to an expression for the surface temperature during spallation as a function of rock physical properties and the incident heat flux. Surface temperature measurements and heat flux determination during laser and flame-jet induced thermal spallation are used to provide appropriate values of the “Weibull parameters” that statistically describe the size-strength relationship in granite. Use of these parameters allows one to accurately estimate surface temperatures required by the numerical simulation model to calculate heat and mass transport rates occurring in the flow field above the spalling rock surface.

Based on the results of this experimental study, we concluded that mechanically-determined Weibull parameters are not directly applicable to describe spallation failure phenomena caused by thermal stress. Under the extreme rapid heating conditions of flame-jet drilling, local overheating and possibly stress relief lead to higher temperatures than predicted using room temperature Weibull parameters. Nonetheless, the Weibull-based statistical model of failure can be utilized by empirically fitting them and σ0 Weibull parameters to match experimental measurements of spalling surface temperature as a function of applied heat flux. Correlations for steady state and onset spallation conditions were established with consistent results obtained for both laser and propane-oxygen flame jet heating.

Similar content being viewed by others

Abbreviations

- A :

-

slope of best-fit line

- C L :

-

spall diameter: thickness ratio

- C P :

-

constant pressure heat capacity (J/kg K)

- E :

-

Young's modulus (MPa); total energy

- G(σ):

-

cumulative probability of failure

- ΔH pt :

-

energy losses due to miscellaneous phase transitions and crack formation (W/m2)

- k r :

-

rock thermal conductivity (W/m K)

- m :

-

Weibull homogeneity parameter

- Q r ,Q :

-

local heat flux to rock (W/m2)

- Q p :

-

predicted heat flux (W/m2)

- Q jet :

-

total jet inlet heat flux (w/m2)

- R noz :

-

nozzle radius (m)

- R h :

-

hole radius (m)

- SOD :

-

dimensionless stand-off distance (Z dr /R dr )

- St :

-

stanton number

- St p :

-

predicted Stanton number based on surface heat flux

- St exp :

-

experimental Stanton number based on measured penetration rate

- t :

-

time (s)

- T :

-

temperature (K)

- T s :

-

local surface temperature (K)

- T ro :

-

initial rock temperature (K)

- T s, st :

-

stagnation point surface temperature (K)

- T jet :

-

gas temperature at nozzle outlet (K)

- U dr :

-

local drilling velocity normal to rock surface (m/s)

- U jet :

-

jet velocity (m/s)

- V :

-

sample volume (m3)

- V dr :

-

forward drilling or penetration rate (m/s)

- Z dr :

-

distance from the bottom of the drill to the stagnation point (m)

- α r :

-

thermal diffusivity of the rock (m2/s)

- β r :

-

thermal coefficient of expansion (V −1 (δV/δT)ρ (K −1)

- σ:

-

local rock stress (MPa)

- σ0 :

-

Weibull parameter (MPa-m3/m)

- ρ r :

-

rock density (kg/m3)

- ν:

-

Poisson's ratio

- dr :

-

drilling related parameters

- exp:

-

experimental value

- jet:

-

property at nozzle outlet conditions

- noz:

-

at nozzle

- r :

-

rock property

- s :

-

rock surface property

- sp :

-

at spallation

- st :

-

at stagnation point conditions

References

Armstead, H. C. H., Tester, J. W. (1987): Heat Mining, Spon, London.

Birch, F., Schairer, J. F., Spicer, H. C. (ed.) (1942): Handbook of physical constants. Goel. Soc. Amer., Special Paper No. 36.

Browning, J. A. (1981): Flame-jet drilling in Conway, N. H. Granite. Unpublished report Univ. of California, Nr. 4-L10-2889R-1.

Browning, J. A., Horton, W. B., Hartman, H. L. (1965): Recent advances in flamejet working of minerals. 7th Symp. Rock Mech., Pennsylvania State Univ., University Park.

Calaman, J. J., Rolseth, H. C. (1961): Technical advances expand use of jet-piercing process in Taconite Industry. Int. Symp. Mining Res., Univ. of Missouri, Columbia.

Carslaw, H. S., Jaeger, J. C. (1959): Conduction of heat in solids. Oxford University Press, Oxford.

Dey, T. N. (1984): More on spallation theory. Los Alamos National Laboratory Internal Memorandum No. ESS-3-286-84.

Dey, T. N., Kranz, R. L. (1985): Methods of improving drilling performance of the thermal spallation drilling system. 9th Conf. Geotherm. Energy, Geotherm. Res. Counc. Transactions Vol. 9, Davis, California.

Hanley, E. J., DeWitt, D. P., Roy, R. F. (1978): The thermal diffusivity of eight well-characterized rocks for the temperature range 300 to 1000 K. Eng. Geol. 12, 31–47.

Krech, W. W., Henderson, F. A., Hjelmstad, K. E. (1974): A standard rock suite for rapid excavation research. U. S. Bureau of Mines Report RI-7865.

Potter, R. M. (1988): pers. comm., Los Alamos, New Mexico.

Preston, F. W. (1934): Observations on spalling. J. Am. Ceram. Soc. 17, 137–144.

Rauenzahn, R. M. (1986): Analysis of the rock mechanics and gas dynamics of flame-jet thermal spallation drilling. Ph. D. Thesis, MIT., Cambridge, Massachusetts.

Rauenzahn, R. M., Tester, J. W. (1985): Flame-jet induced thermal spallation as a method of rapid drilling and cavity formation. In: Proc., 60th Assn. Tech. Conf. and Exhibition, Soc. Petrol. Eng. paper 14331, Las Vegas.

Rauenzahn, R. M., Tester, J. W. (1989): Rock failure mechanisms of flame-jet thermal spallation drilling — theory and experimental testing. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 26 (5), 381–399.

Rauenzahn, R. M., Tester, J. W. (1991a): Numerical simulation and field testing of flame-jet thermal spallation drilling — 1. Model development. Int. J. Heat Mass Transfer 34 (3), 795–808.

Rauenzahn, R. M., Tester, J. W. (1991b): Numerical simulation and field testing of flame-jet thermal spallation drilling — 2. Experimental verification. Int. J. Heat Mass Transfer 34 (3), 809–818.

Tester, J. W., Herzog, H. J. (1990): Economic predictions for heat mining: a review and analysis of hot dry rock (HDR) geothermal energy technology. MIT-EL 90-001, Cambridge, Massachusetts.

Tester, J. W., Herzog, H. J. (1992): The economics of heat mining: an analysis of design options and performance requirements of hot dry rock (HDR) geothermal power systems. Energy Systems Policy 15 (1), 33–63.

Thurumalai, K. (1969): Process of thermal spalling behavior in rocks — an exploratory study. 11th Symp. Rock Mech., Univ. of California.

Weibull, W. (1939): A statistical theory of strength of materials. Invgvetensk. Akad. Handl. 151, 1–45.

Wilkinson, M. A. (1989): Computational modeling of the gas-phase transport phenomena and experimental investigation of surface temperatures during flame-jet thermal spallation drilling. Ph. D. Thesis, MIT, Cambridge, Massachusetts.

Wilkinson, M. A., Tester, J. W. (1993): Computational modeling of fluid flow and heat transfer effects during supersonic flame-jet induced rock spallation (submitted to Int. J. Heat Mass Transfer).

Williams, R. E., Dey, T., Rauenzahn, R. M., Kranz, R., Tester, J. W., Potter, R., Murphy, H. (1988): Advancements in thermal spallation drilling technology. Los Alamos National Laboratory Report LA-11391-MS.

Williams, R. E., Beck, F. E., Potter, R. M. (1991): Thermal spallation drilling research report, Subcontract No. 9-X68-5616R-1. Los Alamos National Laboratory and New Mexico Institute of Mining and Technology.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wilkinson, M.A., Tester, J.W. Experimental measurement of surface temperatures during flame-jet induced thermal spallation. Rock Mech Rock Engng 26, 29–62 (1993). https://doi.org/10.1007/BF01019868

Issue Date:

DOI: https://doi.org/10.1007/BF01019868