Abstract

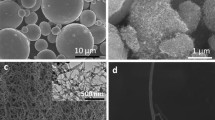

This research paper reports fabrication of iron reinforced with 0.5, 1, 2 and 4 vol.% multi-walled carbon nanotubes (MWCNTs) metal matrix composite (MMC) by powder metallurgy involving mechanical milling in wet (toluene) condition followed by cold compaction and conventional sintering at 900, 1200 and 1300 °C for 2 h under commercial argon gas. The iron-MWCNTs composite powders were milled in a high energy dual drive planetary mill for 10 h and then characterized by using x-ray diffraction (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM). XRD study confirmed the formation of ferrite, austenite and iron carbides (Fe3C and Fe7C3) after milling for 10 h. However, iron carbides were not stable, rather metastable and not visible after consolidation. Hence, iron carbides disappeared and iron oxide (Fe3O4) was formed along with ferrite after consolidation at all temperatures. The optimum relative density, Vickers hardness and compressive strength of 90%, 350 HV, 800 MPa were obtained respectively for 1 vol.% MWCNTs-reinforced iron composite sintered at 1300 °C for 2 h.

Similar content being viewed by others

References

A. Kelly, Composite Materials After 70 Years, J. Mater. Sci., 2006, 41, p 905–912.

P.S. Bains, S.S. Sidhu, and H.S. Payal, Fabrication and Machining of Metal Matrix Composites: A Review, Mater. Manuf. Processes, 2016, 31(5), p 553–573.

S.R. Bakshi, D. Lahiri, and A. Agarwal, Carbon Nanotube Reinforced Metal Matrix Composites -a Review, Int. Mater. Rev., 2010, 55(1), p 41–64.

E. Neubauer, M. Kitzmantel, M. Hulman, and P. Angerer, Potential and Challenges of Metal-Matrix-Composites Reinforced with Carbon Nanofibers and Carbon Nanotubes, Compos. Sci. Technol., 2010, 70, p 2228–2236.

R. George, K.T. Kashyap, R. Rahul, and S. Yamdagni, Strengthening in Carbon Nanotube/Aluminum (CNT/Al) Composites, Scripta Mater., 2005, 53, p 1159–1163.

H.J. Choi and D.H. Bae, Strengthening and Toughening of Aluminum by Single-Walled Carbon Nanotubes, Mater. Sci. Eng., A, 2011, 528, p 2412–2417.

J.P. Salvetat-Delmotte and A. Rubio, Mechanical Properties of Carbon Nanotubes: a Fiber Digests for Beginners, Carbon, 2002, 40, p 729–1734.

E. Saether, S.J.V. Frankland, and R.B. Pipes, Transverse Mechanical Properties of Single Walled Carbon Nanotube Crystals. Pt. I: Determination of Elastic Moduli, Compos. Sci. Technol., 2003, 63, p 1543–1550.

N. Park, D. Sung, S. Lim, S. Moon, and S. Hong, Realistic Adsorption Geometries and Binding Affinities of Metal Nanoparticles Onto the Surface of Carbon Nanotubes, Appl. Phys. Lett., 2009, 94(7), p 073105.

F. Banhart, Interactions Between Metals and Carbon Nanotubes: at the Interface Between Old and New Materials, Nanoscale, 2009, 1, p 201–213.

Y. Zhang, N.W. Franklin, R.J. Chen, and H. Dai, Metal Coating on Suspended Carbon Nanotubes and Its Implication to Metal-Tube Interaction, Chem. Phys. Lett., 2000, 331, p 35–41.

Y. He, J. Zhang, Y. Wang, and Z. Yu, Coating Geometries of Metals on Single-Walled Carbon Nanotubes, Appl. Phys. Lett., 2010, 96, p 063108.

S. Yuan, Y. Kong, F. Wen, and F. Li, Fe4 Cluster Adsorbed on Single-Wall Carbon Nanotubes: A Density Functional Study, Comput. Mater. Sci., 2008, 42, p 83–89.

A.M.K. Esawi, K. Morsi, A. Sayed, A.A. Gawad, and P. Borah, Fabrication and Properties of Dispersed Carbon Nanotube-Aluminum Composites, Mater. Sci. Eng., A, 2009, 508, p 167–173.

O. Boshko, O. Nakonechna, N. Belyavina, M. Dashevskyi, and S. Revo, Nanocrystalline Fe-C Composites Obtained by Mechanical Alloying of Iron and Carbon Nanotubes, Adv. Powder Technol., 2017, 28, p 964–972.

J.Y. Suh and D.H. Bae, Mechanical Properties of Fe Based Composites Reinforced with Multi-Walled Carbon Nanotubes, Mater. Sci. Eng., A, 2013, 582, p 321–325.

Z.Y. Liu, B.L. Xiao, W.G. Wang, and Z.Y. Ma, Single Dispersed Carbon Nanotube/Aluminum Composites Fabricated by Powder Metallurgy Combined with Friction Stir Processing, Carbon, 2012, 50, p 1843–1852.

G. Neumann and C. Tuijn, Interstitial Impurity Diffusion in Metals; the Apparent Size Effect, Physica B, 2002, 315, p 164–170.

A. Slipenyuk, V. Kuprin, Y.U. Milman, J.E. Spowart, and D.B. Miracle, The Effect of Matrix to Reinforcement Particle Size Ratio (PSR) on the Microstructure and Mechanical Properties of a P/M Processed AlCuMn/SiCp MMC, Mater. Sci. Eng., A, 2004, 381, p 165–170.

N. Pierard, A. Fonseca, J.F. Colomer, C. Bossuot, J.M. Benoit, G. Van Tendeloo, J.P. Pirard, and J.B. Nagy, Ball Milling Effect on the Structure of Single-Wall Carbon Nanotubes, Carbon, 2004, 42, p 1691–1697.

W.M. Tucho, H. Mauroy, J.C. Walmsley, S. Deledda, R. Holmestada, and B.C. Hauback, Scripta Mater., 2010, 63, p 637–640.

X. Zeng, Xu. GuoHua Zhou, Y.X. Qiang, Wu. Chao Luo, and Jicai, A New Technique for Dispersion of Carbon Nanotube in a Metal Melt, Mater. Sci. Eng. A, 2010, 527, p 5335–5340.

S. Yoshio, J. Tatami, T. Yamakawa, T. Wakihara, K. Komeya, T. Meguro, K. Aramaki, and K. Yasuda, Dispersion of Carbon Nanotubes in Ethanol by a Bead Milling Process, Carbon, 2011, 49, p 4131–4137.

M.K. Akshay Kumar and U.P. Banerjee, Development of a Novel MWCNT Reinforced Iron Matrix Nanocomposite Through Powder Metallurgy Route, Powder Technol., 2018, 331, p 41–51.

J. Kano and F. Saito, Correlation of Powder Characteristics of Talc During Planetary Ball Milling with the Impact Energy of the Balls Simulated by the Particle Element Method, Powder Technol., 1998, 98, p 166–170.

Y.A. Kim, T. Hayashi, Y. Fukai, M. Endo, T. Yanagisawa, and M.S. Dresselhaus, Effect of Ball Milling on Morphology of Cup-Stacked Carbon Nanotubes, Chem. Phys. Lett., 2002, 355, p 279–284.

B. Munkhbayar, Nasan Bayaraa, Hafizur Rehman, Junhyo Kim, Hanshik Chung, and Hyomin Jeong, Grinding Characteristic of Multiwall Carbon Nanotube-Alumina Composite particle, J. Wuhan Univ. Technol.-Mat. Sci. Edit., 2012, 27, p 1009–1013.

B. Munkhbayar, Md.J. Nine, J. Jeoun, M. Bat-Erdene, H. Chung, and H. Jeong, Influence of Dry and Wet Ball Milling on Dispersion Characteristics of the Multi-Walled Carbon Nanotubes in Aqueous Solution with and Without Surfactant, Powder Technol., 2013, 234, p 132–140.

B.S. Meher, R. Saha, and D. Chaira, Fabrication of Mwcnts Reinforced Iron Metal Matrix Composite by Powder Metallurgy: Effects of Wet and Dry Milling, J. Alloy. Compd., 2021, 872, p 159688.

J.-H. Ahna, H.-S. Shin, Y.-J. Kim, and H. Chung, Structural Modification of Carbon Nanotubes by Various Ball Milling, J. Alloy. Compd., 2007, 434–435(2007), p 428–432.

B.S. Meher, P.R. Samantaray, R. Saha, and D. Chaira, Effect of Dry Milling and MWCNTs Content During Fabrication of Fe-MWCNTs Metal Matrix Composite by High Energy Planetary Milling Followed by Conventional Sintering, Adv. Powder Technol., 2022, 33(2), p 103447.

D. Chaira, B.K. Mishra, and S. Sangal, Efficient Synthesis and Characterization of Iron Carbide Powder by Reaction Milling, Powder Technol., 2009, 191(1–2), p 149–154.

A. Kumar, U. Pandel, and M.K. Banerjee, Effect of High Energy Ball Milling on the Structure of Iron-Multiwall Carbon Nanotubes (MWCNT) Composite, Adv. Mater. Res., 2017, 6(3), p 245–255.

R.S. Longbottom, O. Ostrovski, J. Zhang, and D. Young, Stability of Cementite Formed from Hematite and Titanomagnetite Ore, Metall. and Mater. Trans. B., 2007, 38B, p 175–184.

C.M. Fang, M.H.F. Sluiter, M.A. van Huis, C.K. Ande, and H.W. Zandbergen, Origin of Predominance of Cementite Among Iron Carbides in Steel at Elevated Temperature, Phys. Rev. Lett., 2010, 105, p 055503.

G. Polat, I. Emre-Canbolat, A. Uzunog˘lu, and H. Kotan, Effect of Milling Time, MWCNT Content, and Annealing Temperature on Microstructure and Hardness of Fe/MWCNT Nanocomposites Synthesized by High-Energy Ball Milling, Adv. Powder Technol., 2021, 32, p 3107–3116.

A. Kumar, U. Banerjee, M.K. Chowrasia, H. Sekhar, and M.K. Banerjee, Effect of MWCNT Content on the Structure and Properties of Spark Plasma Sintered iron-MWCNT Composites Synthesized by High-Energy Ball Milling, J. Mater. Eng. Perform., 2019, 28(5), p 2983–3000.

Funding

This research did not receive any specific grant from public, commercial, or not-for-profit funding agencies.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meher, B.S., Saha, R., Sahoo, B.K. et al. Effect of Wet Milling and Reinforcement Content on Iron-Multi-walled Carbon Nanotube Metal Matrix Composite Fabricated by Conventional Powder Metallurgy. J. of Materi Eng and Perform 32, 3755–3771 (2023). https://doi.org/10.1007/s11665-022-07352-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07352-9