Abstract

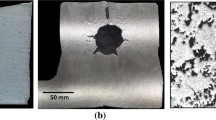

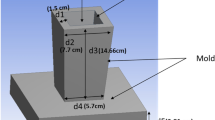

A commercial software package, MAGMASOFT (MAGMA Giessereitechnologie GmbH, Aachen, Germany), was used to study shrinkage and gas porosity in titanium dental castings. A geometrical model for two simplified tooth crowns connected by a connector bar was created. Both mold filling and solidification of this casting model were numerically simulated. Shrinkage porosity was quantitatively predicted by means of a built-in feeding criterion. The risk of gas pore formation was investigated using the numerical filling and solidification results. The results of the numerical simulations were compared with experiments, which were carried out on a centrifugal casting machine with an investment block mold. The block mold was made of SiO2 based slurry with a 1 mm thick Zr2 face coat to reduce metal–mold reactions. Both melting and casting were carried out under protective argon (40 kPa). The finished castings were sectioned and the shrinkage porosity determined. The experimentally determined shrinkage porosity coincided with the predicted numerical simulation results. No apparent gas porosity was found in these model castings. Several running and gating systems for the above model casting were numerically simulated. An optimized running and gating system design was then experimentally cast, which resulted in porosity-free castings. © 1999 Kluwer Academic Publishers

Similar content being viewed by others

References

H. HerØ, M. Syverud and M. Waarli, J. Mater. Sci.: Mater. Med. 4 (1993) 296.

H. HerØ, M. Syverud and M. Waarli, Dent. Mater. 9 (1993) 15.

T. I. Chai and R. S. Stein, J. Prosth. Dentistry 73 (1995) 534.

I. Watanabe, J. H. Watkins, H. Nakajima, M. Atsuta and T. Okabe, J. Dent. Res. 76 (1997) 773.

O. N. Magnitskiy, in “Casting properties of titanium alloys”, edited translation (CLEARING-HOUSE for Federal Scientific and Technical Information Springfield, VA, 1970) pp. 5 and 92.

M. Syverud and H. HerØ, Dent. Mater. 11 (1995) 14.

K. Watanabe, S. Okawa, O. Miyakawa, S. Nakano, N. 5hiokawa and M. Kobayashi, Dent. Mater. J. 10 (1991) 128.

J. Campbell, in “Castings” (Butterworth Heinemann, London, 1991) 16.

O. Miyakawa, K. Watanabe, S. Okawa, S. Nakano, H. Honma, M. Kobayashi and N. Shiokawa, Dent. Mater. J. 12 (1993) 171.

M. Augthun, L. Becker, H. Kreutzer, P. R. Sahm, W. SchÄfer and J. SchÄdlich-stubenrauch, Deutsche Zahnärztliche Zeitschrift 44 (1989) 849.

H. Kreutzer, W. SchÄfer, J. SchÄdlichstubenrauch and P. R. Sahm, Dent. Lab. 37 (1989) 908.

J. SchÄdlich-stubenrauch and P. R. Sahm, Giessereiforschung 43 (1991) 141.

P. R. Sahm, in “Formfüll-und Erstarrungs-simulation-Ein Ñbersicht, Guss-Produkte'94” (Hoppenstedt *Co., Darmstadt-Berlin, 1994) 237.

P. N. Hansen, G. C. Hartmann and J. C. Sturm, AFS Trans. 99 (1991) 477.

D. M. Lipinski, W. SchÄfer and E. Flender, in Proceedings of 4th International Conference on Modeling of Casting, Welding and Advanced Solidification Process, Florida, USA, March 21-26, 1993, p.389.

P. R. Sahm and P. N. Hansen, in “Numerical simulation and modeling of casting and solidification process for foundry and cast-house” (Comite Int. des Associations Techniques de Fouderie, Zurich, 1984).

R. Boyer, G. Welsch and E. W. Collings, in “Materials properties handbook: titanium Alloys” (ASM International, Materials Park, 1994) 125.

Y. S. Touloukian, R. W. Powell, C. Y. Ho and P. G. Klemens, in “Thermophysical properties of matter: thermal conductivity-metallic elements and alloys”, The TPRC Data Series (1) p.414.

Y. S. Touloukian and E. H. Buyco, in “Thermophysical properties of matter: specific heat-metallic elements and alloys”, The TPRC Data Series (4) p.260.

K. Suzuki, K. Ni Shikawa and S. Watakabe, Mater. Trans. JIM 37 (1996) 1793.

J. Takahashi, J. Z. Zhang and M. Okazaki, Dent. Mater. J. 12 (1993) 245.

J. D. Preston and R. Berger, Dent. Clin. North Am. 21 (1977) 717.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wu, M., Sahm, P.R., Augthun, M. et al. Numerical study of porosity in titanium dental castings. Journal of Materials Science: Materials in Medicine 10, 519–525 (1999). https://doi.org/10.1023/A:1008960129350

Issue Date:

DOI: https://doi.org/10.1023/A:1008960129350